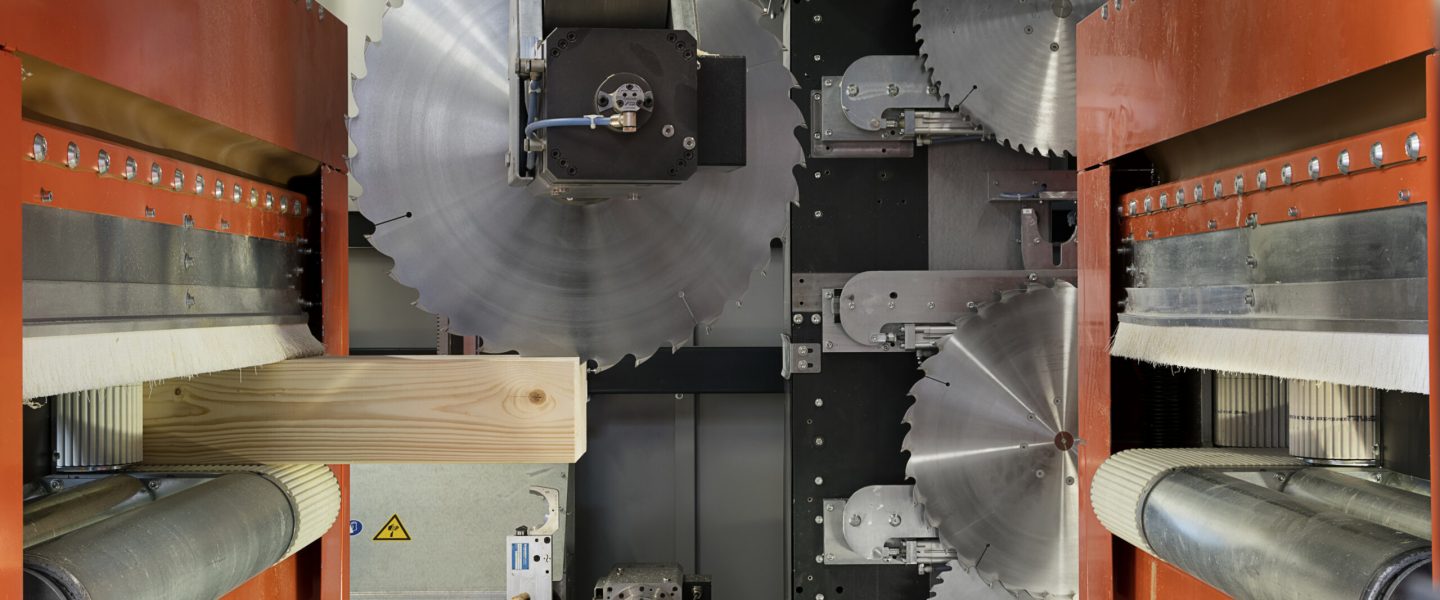

Conventional beam joining with small to very large dimensions, entire beam packages, plates, bulky glulam elements or box elements and even 3-dimensional molded parts are processed efficiently, precisely and with a high degree of flexibility.

Two water-cooled 5-axis spindles à 29 kW process the component very efficiently thanks to the 2-channel control; while one spindle is working, the second spindle changes the tool. Six-sided machining of the components is possible thanks to the spindles, which can move out of the machining area on the Y-axis.