The TW-Mill M extension version impresses with its high flexibility, which is achieved by the open machining area. Components can be machined along the entire length of the machine table – which can optionally be made of wood by the operator.

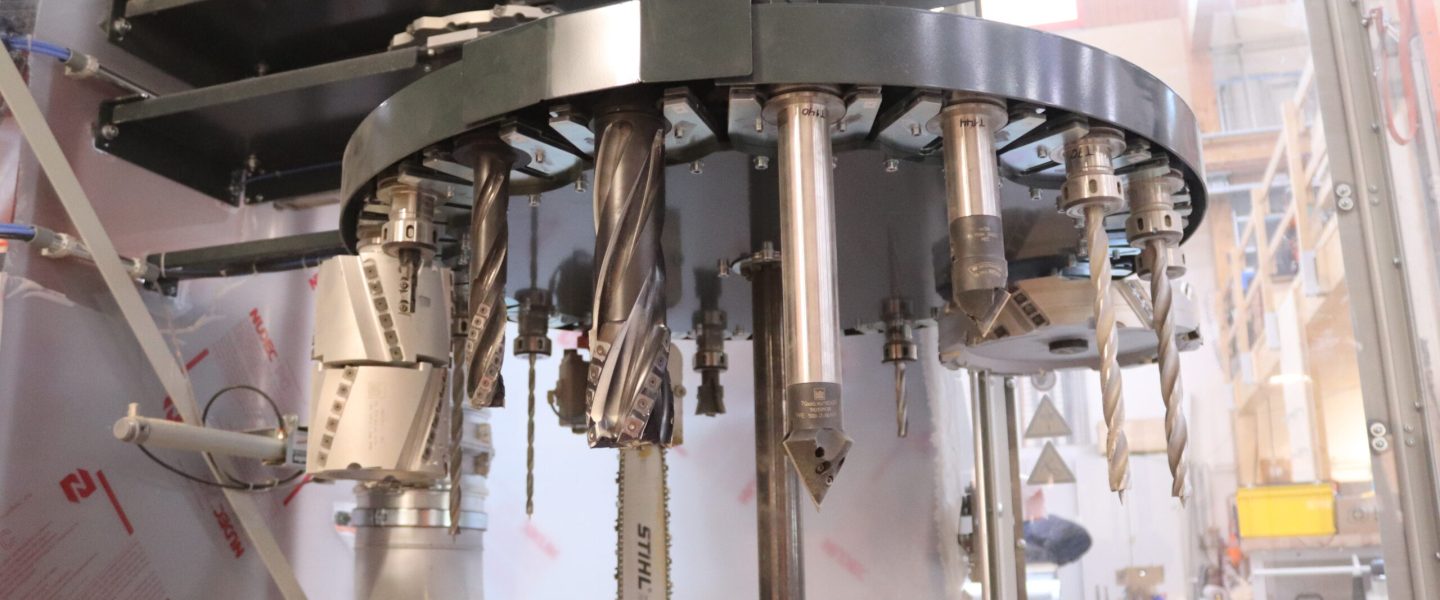

The basic version includes a 5-axis spindle unit. The Y-axis is designed so that the spindles can be moved out of the table area. This allows full machining from all 5 sides, including deep horizontal holes on all sides.

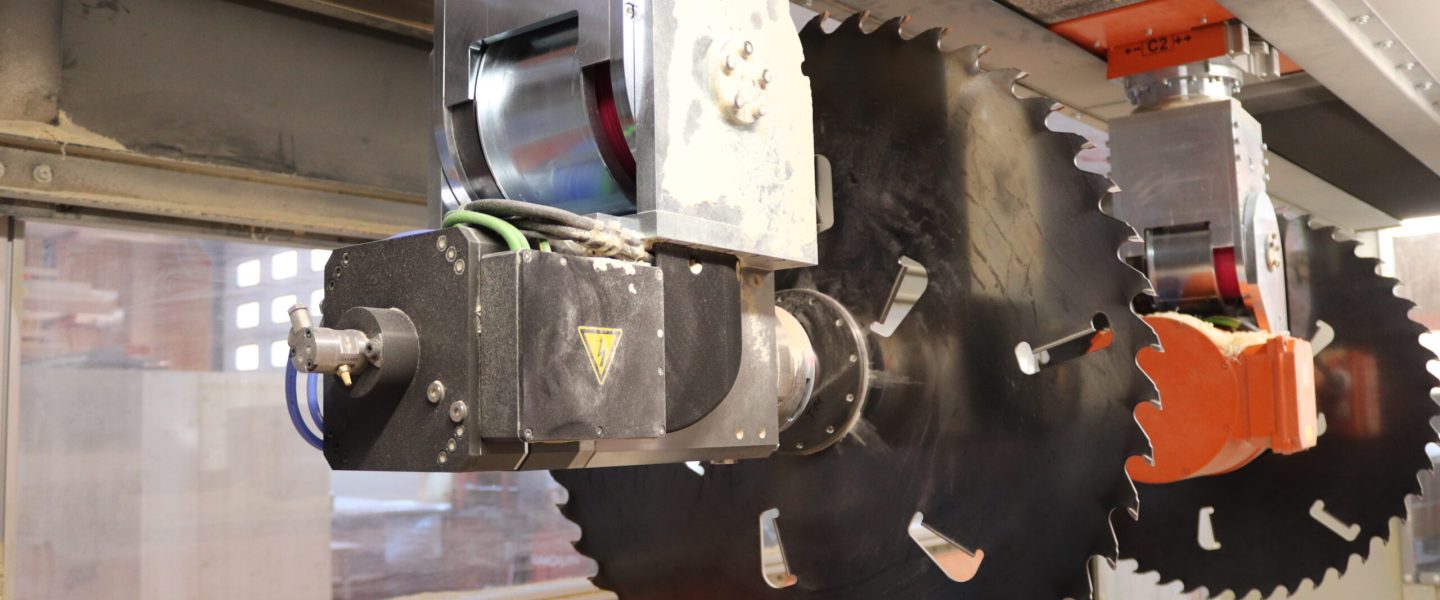

Optionally, an additional 5-axis sawing unit can be installed on the gantry. With the use of this second sawing unit, the tasks are distributed between the spindle unit and the sawing unit. This guarantees optimum force and speed for the respective machining task.

The clamping elements required for clamping and workpiece machining are planned jointly by the project parties, based on the requirements of the components planned for production, as well as the technical application geometries of the machining spindles and units of the system.